Vibration Analysis

For a machine in motion certain reactions like vibrations are inevitable and therefore a pre-hand check of balanced limits for the same is mandatory. When it exceeds the limit, it is unhealthy for the function of the machine. Our solutions therefore keep that in check by doing a VIBRATION ANALYSIS on a regular basis. Through our efficient analysis, we understand the workings of the machine and its system therefore eliminating the possibility of any future problem. This avoids unexpected failures and unprepared machine maintenance. We provide this service to ensure it does not hinder your ongoing progress.

ENQUIRE NOW

IN-SITU DYNAMIC BALANCING

Rotating machines fall prey to imbalance because of increased vibration. This causes a hindrance in the smooth functioning of the machine due to stress created by the imbalance. This in turn results in increased energy consumption and reduced production time. And this causes inefficiency in the chain of progress and work. In-Situ Dynamic Balancing can reduce need for machinery removal. The typical applications that can be benefitted with this service are

- Fans & Blowers

- Centrifuge Rotor

- Electric Motor Rotors / Armatures

- Compressor Rotor

- Impellers

- High Speed Machine Tool Components

- Turbine Rotors

ENQUIRE NOW

SHAFT ALIGNMENT SERVICE WITH LASER BASED TECHNOLOGY

The problems caused by the misalignment of the shaft are many, like it leads to increased friction and energy consumption, premature failure of bearings/ shaft/ coupling/seals, and most importantly unplanned downtime. We as service providers, take complete care to present remedy for the problem well in advance. We use the laser based technology as because it is the only way to align shaft in horizontal, vertical and angular position. We have a dedicated team and latest tools to execute the job. We believe and work towards creating solutions for the possible and predictable problems.

ENQUIRE NOW

BELT ALIGNMENT SERVICE WITH LASER BASED TECHNOLOGY

Smaller components in a machine are responsible for the smooth functioning of the machine therefore if even a small part gets affected, it affects the complete process in whole. V-belts are usually seen as those parts that seem too small to be taken seriously and therefore no one takes care to avoid its early failure. However, the pulleys must be aligned correctly in all three dimensions whether horizontal, vertical, parallel or in combination because if they are not aligned as per the structure it causes higher friction that leads to high energy consumption. With our laser based tool kits it is possible to align the pulley grooves which is the best solution to reduce frictions, save energy and also extend the productive life of the components.

ENQUIRE NOW

THERMOGRAPHY

Thermography is very essential for locating the defects and therefore making it easier to take corrective measures. How do you know that you need thermography? Any rotating equipment can face problems due to the heat originating that causes temperature deviations. These problems can be related to bearings, seals, and alignment faults. Other reasons can be variations in process flows, valve faults, electrical contact, or flashover problems. Through thermography these can be detected effectively with the help of a thermal camera which allows the results to be documented in colour images with temperature scales. This report comes with appropriate corrective measures that can avoid costly failures from occurring. Our service takes care of everything and saves you time, energy, and money of investing in a thermal imaging camera and an expert engineer to diagnose the problem.

Activities carried out during a Thermography service include:

- Inspection with a thermal camera

- Analysis of thermal and visual inspection data

- Presentation of findings and repair recommendations

ENQUIRE NOW

HYDRAULIC CYLINDER REPAIR AS A CUSTOMIZED REQUIREMENT

A component you cannot take lightly, the HYDRAULIC CYLINDERS are one of the most important products wherever used in the system. Sudden failure of the same can cause many problems for the Maintenance team.

We provide complete solutions to below stated issues faced in cylinders:

- Bent Rod

- Ballooned Tube

- Insufficient Bearing Area

- Poor Rod Finish

- Poor Seal Quality

ENQUIRE NOW

IDLER ROLLER REPAIRS / NEW IDLER ROLLER

The failure of Idler Roller always finds its cause in poor seals and poor bearing quality. The failure of Idler Rollers therefore leads to damage of the conveyor belts. This is mainly because of the jamming of the Idler Rollers that are caused by poor bearing. To tackle this problem, we design absolutely befitting rollers, seals, and bearings to eradicate the problem of fitting issues. We also undertake repairs of existing rollers and fix the bearing and seal problems too. We help set up everything with a thorough check and follow up. We also sometimes replace it with new rollers as per the deal with the customer.

ENQUIRE NOW

OIL ANALYSIS

Oil analysis is a routine activity for analyzing oil health, oil contamination and machine wear. The purpose of an oil analysis program is to verify that a lubricated machine is operating according to expectations. When an abnormal condition or parameter is identified through oil analysis, immediate actions can be taken to correct the root cause or to mitigate a developing failure. We follow the ASTM International standards to improve plant reliability to global benchmarks.

An obvious reason to perform oil analysis is to understand the condition of the oil, but it is also intended to help bring to light the condition of the machine from which the oil sample was taken. There are three main categories of oil analysis: fluid properties, contamination and wear debris.

With oil analysis, careful oil samples are taken, and elaborate machines yield the test results. Our laboratory personnel interprets the data to the best of their ability, but without crucial details about the machine, a diagnosis or prognosis can be inaccurate. Therefore, we save you the hassle and present professional reports for the best of your machine functioning.

BEARING MOUNTING

When a bearing is mounted improperly without utilizing the correct techniques and tools the bearing’s service life will be jeopardized. An estimated 16 percent of all premature bearing failures can be directly attributed to poor fitting (usually due to brute force installation) and the absence (or lack of knowledge) of the correct fitting tools. Using best practices for mounting a bearing can help avoid future problems and ultimately extend bearing performance and longevity in service. Along the way, both the efficiency and productivity of an operation can advance with an associated increase in machinery uptime.

Rolling bearings play vital roles in rotating machinery by helping to reduce friction, transmit loads, and locate and support shafts. Thousands of bearing types and styles offer a wide range of solutions suitable for fluid movement applications. At the beginning of the application, success or failure originates with the mounting process. Therefore our team of highly skilled engineers train and provide supervision on the right techniques to the end users.

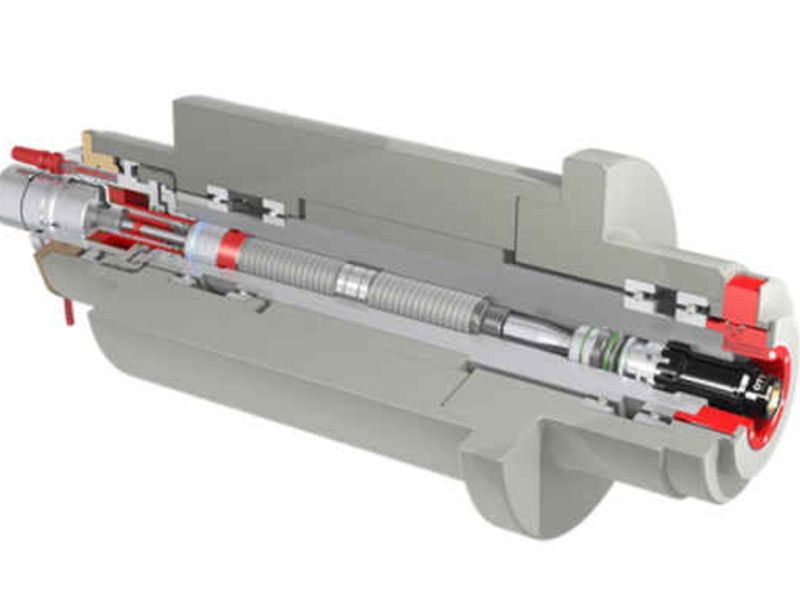

SPINDLE REFURBISHMENT

Our Spindle refurbishment is a fast and an efficient process that prolongs the service life. To ensure thereby a reliable future spindle performance, reconditioning must be comprehensive. We take into consideration all the major components that cannot be ignored. Everything we do in the process of refurbishment is to make sure that the repair is done at all levels to make it last that much longer. This saves you time and money all at once.

ENQUIRE NOW

BEARING REFURBISHMENT

Our Bearing Refurbishment facility extends to large size bearings. We make sure that every little repair and change in the bearing is taken care of by us at all levels. We specialize in bearing assistance and maintenance. Our step by step process therefore helps in

- Revitalizing your inventory

- Unnecessary Scrapping

- Reduces Life Cycle Cost

- Extending Operating Life Cycle

ENQUIRE NOW